VITROLUBE 1220c

Our previous discussion on modifications to the basic 1220 formula dealt only with results from our in-house testing. Since that time, other companies using different test machines and criteria have run comparative tests with the basic 1220 coating and the modified 1220C coating and have obtained increased performance similar to our in-house tests.

Table III summarizes the results using three different test machines including our pin and vee groove machine. This table illustrates that all three procedures show similar improvement in performance even though they differ greatly in specimen configuration and test conditions.

In addition to the test data shown in Table III, the Vitrolube NPI-1220C has been tested on actual hardware for some of the newer aerospace designs and the results have been consistently superior to other tested products. A number of these designs have involved gears and screw threads which are applications where dry film lubricants are not normally considered to be at their best but where the 1220C coating has been consistently superior to other coatings, and has exceeded all design requirements.

Intended Use

As originally conceived, the Vitro-Lube coating was intended for use as a high temperature lubricant (to +650°F) in plain journal (bushings) and plain spherical bearings applications involving low velocity oscillatory motion at high units stress loads (10,000 to 50,000 psi). It was to be used in applications where more conventional grease type lubricants or TFE liners were not suitable either because of temperature limitations or other design considerations. As more test data was accumulated, the exceptional cryogenic and room temperature capabilities of the coating became apparent and its use is no longer limited to high temperature applications. The very stringent quality control necessary for the manufacture and processing of this coating provides a more reliable product in applications where conventional resin bonded coatings have been used in the past.

Vitro-lube is that very unique lubricant that should be specified after the greases, TFE liners, and conventional dry film lubricants have proven inadequate.

Suggested Applications

The following list indicates some of the successful applications for Vitro-Lube:

Gimbal bearings

- Flex duct bearings

- Journal bearings

- Acme screw threads

- Slides, ramps, hinges

- Splines, shafts, bushings

- Gears

- Ball screws

- Rolling elements

- Static pins

- Reverser linkage

- Latches, cams

- Rollers, clevises

- Threads, seals

- Poppets

We do not infer success in all applications, but we can state that if a solid film dry lubricant will satisfy your requirements, Vitro-Lube would be the lubricant most likely to provide optimum performance over a wide temperature range and substantially longer wear life.

Appearance

In its finished form, Vitro-Lube is similar in appearance to more conventional dry film lubricant coatings. It is dark gray to black with a matte finish. It is a continuous smooth coating that burnishes readily when handled.

Thickness

The nominal thickness is 0.0005 to 0.0009 inches of which two thirds is the base coat and one third is the top coat.

Cure Cycle

The heating cycle required to bond the Vitro-Lube base coat to the metal surface is critical and consequently very precise. In order to soften the ceramic frit and allow proper bonding, the surface of the coated part is brought to a temperature of +975°F and held for one minute. This is accomplished in high heat recovery kilns in an oxygen atmosphere.

Failure to reach the proper temperature will prevent adequate softening of the ceramic frit causing a total lack of adhesion. Excessive time at temperature can result in burning of the coating which causes a degradation of the coating and a loss in wear life. The top coat is subsequently applied over the base coat and cured for one hour at +300°F for the NPI-1220 and +575°F for the NPI-1220C.

Contaminants

For optimum results, contamination of the Vitro-Lube coated bearing surface should be avoided. Abrasive substances such as sand or metallic powder (from grinding) will definitely shorten the wear life of the coating. Fluids of any type that are on the coated surface during motion of the part will seriously degrade the wear life of the coating. This is true of all known dry film lubricant coatings and Vitro-Lube is considered to be less affected than most other dry films. The coating will withstand immersion in all fluids common to aircraft and space vehicles without washing off. No significant damage will result provided the fluids are removed prior to use.

Some fluids used in typical machining operations are especially harmful to the coating and extreme care should be taken whenever any type of machining is contemplated on parts that have been coated with Vitro-Lube (such as machining of outer races of swaged plain spherical bearings).

Metal Substrate Selection

The selection of a compatible material to accommodate Vitro-Lube has never posed a problem as it lends itself to almost all metals common to the airframe and engine industry today. For best results, we suggest a hard, reasonably smooth surface (RHR 32) that in itself possesses the required corrosion resistance.

Clearance

When mating parts of an assembly are to be coated with Vitro-Lube, such as a plain journal bearing and it’s mating shaft, a minimum clearance of .0005″ should be maintained. The end of the shaft and the inside edge of the bushing should be radiused to facilitate assembly without damage to the Vitro-Lube coated wear surface.

Environment

Vitro-Lube was originally developed for a maximum temperature environment of 630°F; however, we feel it is within its capabilities to be specified for environments up to 900°F, although wear life will be significantly reduced. It has been exposed to cryogenic temperatures and sodium vapors with no apparent deleterious effect. Vitro-Lube has an established compatibility with the space environment as it remains stable in a hard vacuum; it does not volatilize or outgas. Vitro-Lube has been certified as non-impact sensitive.

General Design Suggestions

- Vitro-Lube should be applied to both mating wear surfaces whenever possible for maximum wear life. Coating of both surfaces increases wear life by a factor of three based on a number of test procedures.

- Where used to prevent fretting or in a static pin joint, Vitro-Lube may be applied to only one surface.

- Where only one surface can be coated it should be applied to the continuously loaded member.

- To order the application of Vitro-Lube to a specific area of a detail part, the following must be shown on the manufacturing drawing: Apply Vitro-Lube NPI-1220 to the area shown. Source: National Process Industries, 42250 Baldaray Circle, Temecula, California 92590.

- In those cases where a company specification exists, that shall be the controlling document. Companies that have prepared their own specifications include: Arrowhead Products, Astro Aerospace Northrop Grumman, Boeing, Boeing Integrated Defense Systems, Lockheed Martin, MD Robotics, Aerojet Rocketdyne and Raytheon (Hughes).

Wear Life Testing

The best wear life tests are conducted with the actual assembled hardware, using techniques and procedures that are the same as those used in production, and tested in the same environment in which it is intended for use. Temperature and contamination environment and the same start-stop intervals and the same lull periods should be duplicated as closely as possible. However, the time required to duplicate actual operating conditions may not be available, so the next best thing is the accelerated bench test. This type of test serves best as a screening tool.

Below we will describe several different types of bench tests. Possibly there is one that is similar in geometry and mechanics to an application you have in mind. If so, you may be able to get some indication of whether or not Vitro-Lube will meet your needs. If your extrapolation shows promise, then this should be regarded as justification for an actual test of production components. The following test data were generated outside of our facilities.

Journal Bearing Test

This test technique was used by North American during the development of this coating and simulates typical air frame bearing usage. Figure 1 presents curves of cycle life versus loading at various temperatures, and Figure 2 compares Vitro-Lube to an accepted sodium silicate bonded dry film lubricant. More details of this test technique and the results can be obtained by contacting NPI.

North American during the development of this coating and simulates typical air frame bearing usage. Figure 1 presents curves of cycle life versus loading at various temperatures, and Figure 2 compares Vitro-Lube to an accepted sodium silicate bonded dry film lubricant. More details of this test technique and the results can be obtained by contacting NPI.

* Figure 1 presents curves of cycle life versus loading at various temperatures

* Figure 2 compares Vitro-Lube to an accepted commercial sodium silicate bonded dry film lubricant.

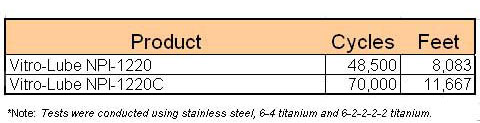

Timken Ring and Conforming Block Test (1996)

These tests were conducted using a Timken Ring and  conforming block test machine which subjects the coating to a unit pressure of 1900 psi, a speed of 50 cycles per minute (oscillating), an amplitude of oscillation of 60 degrees, and at room temperature. Test materials were 17-4 PH corrosion resistant steel. The following is a comparison between Vitro-Lube NPI-1220 and NPI-1220C.

conforming block test machine which subjects the coating to a unit pressure of 1900 psi, a speed of 50 cycles per minute (oscillating), an amplitude of oscillation of 60 degrees, and at room temperature. Test materials were 17-4 PH corrosion resistant steel. The following is a comparison between Vitro-Lube NPI-1220 and NPI-1220C.

| PRODUCT | CYCLES |

| Vitro-Lube NPI-1220 | 197,000 |

| Vitro-Lube NPI-1220C | 335,000 |

* Based on these results, the 1220C coating has been added to an existing user specification for use on newer design applications.

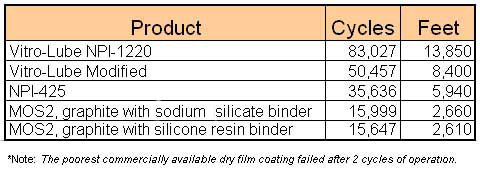

Rider and Plate Test

(1968 – 1970) at +450°F

These tests were conducted using circular riders made of 440C stainless steel and flat rectangular plates made of 17-4PH stainless steel. Both the rider and the specimens were accomplished through an air cylinder and lever system. The flat plate was attached to a table and reciprocated under the rider by a mechanical drive system. The stress level at the contact area between the rider and the plate was 10,000 psi; the stroke length was one inch (two inches per cycle); the speed of reciprocation was 33 cycles per minute; the test temperature was 450°F. Failure occurred when the friction coefficient reached 0.45.

This test program evaluated twenty-two commercial dry film lubricant products, the best of which are reported as follows:

In a 1996 test, the rider and flat plate test machine subjects the coating to a unit pressure of 10,000 psi, temperature of +500°F, a speed of 33 reciprocating cycles per minute and a motion of ±0.5 inches (2 inches per cycle).

Material combinations consisted of 440C versus 17-4, 6-4 titanium versus 6-4 titanium, and 6-2-2-2-2 titanium versus 6-2-2-2-2 titanium. Based on these results, the 1220C coating is being added to an existing user specification for use on newer design applications.

Quality Control Testing

Pin and Vee Block (Falex Test)

This test technique is the one used at our facility, primarily as a quality control tool. It is conducted in accordance with ASTM test method D2625-69 using 4130 Steel Rc41-45. This test is not considered to be a meaningful test in terms of predicting wear life as the test parameters and the geometry of the test specimens are not typical of those found in airframe hardware. The technique, however, does provide batch to batch performance verification as well as comparative data with other coatings.* Testing per ASTM D 2625 Procedure A – The normal load is 1000 lbs gage which translates to about 219,000 psi Hertzian contact stress.

The following is a comparison of Vitro-lube NPI-1220 and 1220C based on batch check tests:

| PRODUCT | HOURS |

| Vitro-lube NPI-1220 | 8.8 |

| Vitro-lube NPI-1220C | 14.0 |

The Falex tester is used as a standard ASTM testing device for many types of lubricants. It utilizes a 1/4 pin located between two vee blocks as illustrated in the above diagram. It is capable of applying very high loads and running for the life of the lubricant. The test machine operates at room temperature only, unless oil tests are being done, whereby the oil may be heated in a cup.

The tester measures a torque indicative of the frictional value of the lubricant. With dry film testing, the frictional torque causes heating of the specimens. Although the tester is at room temperature, the frictional heat may cause the specimen pin temperature to rise to 300-350F, thus really testing the lubricant at some indeterminate temperature above that of the ambient condition. It doesn’t have the capability of artificially heating the specimens nor conducting tests at predetermined temperatures. It is used extensively to judge and compare lubricants and to provide quality or specification controls for lubricants.

A note about testing per ASTM D2625-69: This specification indicates the use of test specimens fabricated from AISI 4130 steel, heat-treated to 180,000 – 200,000 psi (Rc 41-45), or as an alternative, V-Blocks of AISIC 1137 steel with a hardness of HRC 20-24 (108,000-117,000 psi), and pins of SAE 3135 steel with a hardness of HRB 87-91 (83,000-91,000 psi). The specification does not indicate that there is a difference in wear life based on the use of different test specimen material. However, wear life results will vary depending on the material combination, especially when using the softer test specimens. This should be considered when evaluating performance for different substrates.

The pin and V-Block test machine is manufactured by the Falex Corporation and was specified use for qualification purposes on military specification (e.g. MIL-L-8937 and MIL-L46010). It was selected by the military based primarily on the work reported by the Coordinating Research Council in CRC Report No. 419, dated August 1968.

Summary

Because Vitro-Lube is relied upon as the sole means of lubrication, and failure could result if it does not perform to its expected capability, two conditions are felt to be mandatory. First, NPI must ensure that product quality is consistent. Second, the user must be sure the Vitro-Lube coated surfaces are not damaged by handling or during assembly.

With the advent of even more sophisticated aircraft and aerospace vehicles, we feel confident we will be called upon to perform to an even more exacting degree. We eagerly await the challenge.